11th Refining & Petrochemical Innovation Conference Indonesia 2025

AUG. 27-28 | JAKARTA, INDONESIA | IN-PERSON EVENT

Refiners can now take a strong lead into a new, profitable business area. Advanced chemical recycling via feedstock is a technology that has emerged that allows companies to turn waste into income and produce clean, premium feedstock for steam crackers. Being a first mover into this area is a promising avenue for refineries to utilize the assets they already have to provide a feedstock for producing circular plastic. In doing so you can meet the increasing demand from petrochemical companies and their customers (or brand owners) for a more sustainable, circular plastic product.

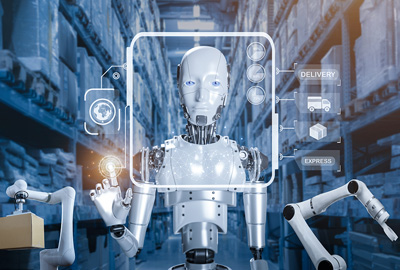

The digital transformation is redefining the context of operational excellence. Over 79% of refining and petrochemical professionals are very confident that an operational excellence (OE) mindset will result in safer, more reliable and profitable operations. Digitalization is the essential tool; unleashing the power of data to meet the challenges—and to be more profitable while doing so. An underlying enabler of industrial digitalization, the integration of IT and OT has been playing out slowly for decades. But it is now gathering massive momentum and delivering a vast array of new possibilities.

Catalytic processes are at the heart of all refineries and petrochemical complexes. The global catalyst market is booming, with continuous technology developments in catalyst production, optimization and increased efficiency in achieving operating goals. This trend is especially true in the refining sector where the use of catalytic processes is on the constant rise. The Global Catalyst market is forecasted to grow at CAGR of 4.6% by 2024 – further expansion is expected with developments in refining, petrochemicals, chemicals and evolving environmental factors – all increasing demand for more performant catalysts, and investment in R&D. The demand in refining catalysts is forecasted to reach over $4.7 bln. this year (annual growth slightly lower than global sales of all catalysts – 3.6% per annum – signs of a potential misbalance in some regions, esp. on mature markets, in the upcoming few years).

The energy transition and electrification of transport will slow the pace of global gasoline demand growth and ultimately drive it into reverse. Meanwhile, the versatility and durability of petrochemicals ensures sustained demand growth, particularly in the developing economies of Asia. (Somewhat tempered by the increase in recycling driven by the global war on plastic waste.) This overarching mega-trend promotes the adoption of refinery-petrochemical integration, particularly for new facilities. Already, more than 30% of the world's refineries are now integrated with commodity petrochemicals. These sites benefit from both a diversified product slate, and the potential to unlock greater value through economies of scale and operational cost synergies.

Bio-based raw materials and associated process technologies form an entirely new engineering challenge for integrated petroleum refineries. The composition variation of raw materials, including trace components, various logistical problems and the difficulty of coming up with the right integration approach compared to conventional engineering of fuel refineries using petroleum feedstocks, needs new types of skills and experience. The fundamental engineering challenge is to combine existing advanced petroleum process technologies with various aspects of the problems faced in renewable fuels process engineering and to come up with the optimal design approach that enables the implementation of biomaterial streams to the highly integrated process environment of a petroleum refinery.

The hydrogen economy is gaining momentum, and technologies are playing a key role in helping manufacturers to unlock the potential of this light gas. Even petrochemical groups that refine crude oil are starting to transition to a more sustainable future built on H2. Integrated refinery and petrochemical operations use huge volumes of hydrogen, for example to desulfurize the fuels they produce. However, the application opportunities for H2 extend far beyond desulfurization, as one of our largest refinery and petrochemical customers is demonstrating. Refineries require huge amounts of hydrogen. And companies that convert low-grade crude oil into low-emission fuels need even more of this light gas, integrate hydrogen technologies enabling even highly sulfurous crude oil to be refined into high-grade, low-emission fuels.

Main Conference

Sub-Streams

Buffet Lunch

Documentation Package

Main Conference

To know more Brands

3 One to One Meetings

Known by 200+ Delegates

Reported by all Media Partners

Main Conference

Standard Exhibition Booth

3 One to One Meetings

Sub-Streams

Documentation Package